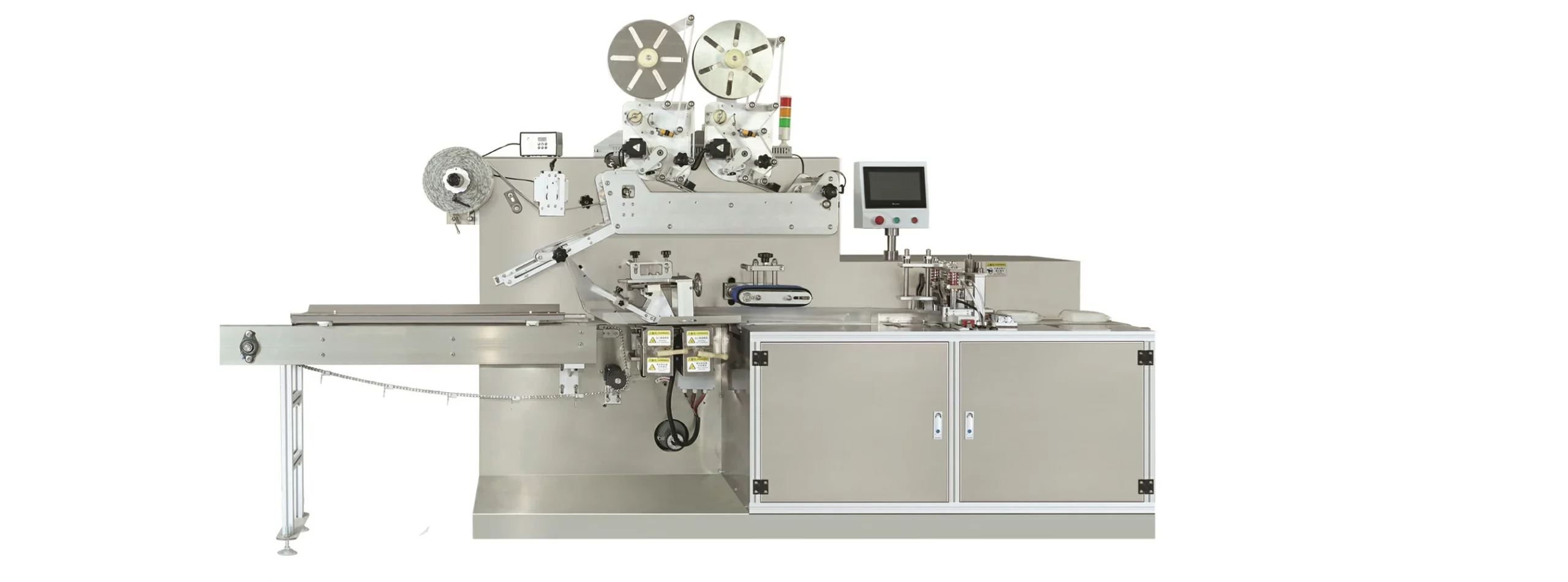

To stay ahead of the curve in the wet wipe industry, investing in state-of-the-art wet wipe packaging machines is crucial. These advanced machines incorporate cutting-edge technologies and features that optimize productivity, efficiency, and product quality. Here are some key elements of state-of-the-art wet wipe packaging machines:

High-Speed Performance:

State-of-the-art machines are designed by wet wipe packaging manufacturer for high-speed performance, enabling faster packaging cycles and increased production throughput. They employ advanced motion control systems, optimized mechanical designs, and efficient material handling mechanisms to achieve maximum productivity.

Intelligent Packaging Control:

These machines feature intelligent packaging control systems that monitor and adjust key parameters in real-time. This includes precise control of packaging material tension, temperature, and sealing pressure to ensure consistent and reliable seal integrity. Intelligent control also minimizes material waste and reduces the risk of product spoilage.

Advanced Material Handling:

State-of-the-art packaging machines employ advanced material handling systems for smooth and efficient processing. They incorporate robotic arms, conveyor systems, or automated feeders to precisely position and transfer wet wipes during the packaging process. These systems minimize handling errors, improve accuracy, and optimize overall production efficiency.

Vision Systems and Quality Assurance:

Integration of vision systems and quality assurance mechanisms is a key component of modern wet wipe packaging machines. High-resolution cameras and intelligent algorithms inspect each wet wipe for defects, ensuring only high-quality products reach the market. These systems can detect issues like folding errors, contamination, or missing wipes, enhancing product consistency and customer satisfaction.

Customization and Flexibility:

State-of-the-art machines offer customization and flexibility options to meet diverse customer demands. They can handle various wet wipe formats, sizes, and packaging configurations, allowing manufacturers to easily adapt to changing market trends. Quick changeover mechanisms and adjustable settings enable seamless transitions between different product variations.

Sustainability and Eco-Friendly Features:

Modern wet wipe packaging machines prioritize sustainability by incorporating eco-friendly features. They use recyclable or compostable packaging materials, minimize material waste, and optimize energy consumption through energy-efficient components. These machines align with the growing demand for environmentally friendly practices and support corporate social responsibility initiatives.

IoT Connectivity and Data Analytics:

State-of-the-art packaging machines are IoT-enabled, allowing for connectivity, data collection, and analysis. They can gather real-time production data, machine performance metrics, and maintenance insights. Leveraging data analytics and machine learning algorithms provides valuable insights for optimizing production efficiency, predictive maintenance, and quality control.

User-Friendly Interfaces:

These machines feature intuitive and user-friendly human-machine interfaces (HMIs) that simplify operation and setup. Touchscreen displays, graphical interfaces, and guided workflows make it easy for operators to control and monitor the packaging process. Clear visualizations and step-by-step instructions minimize the learning curve and reduce the risk of errors.

Remote Monitoring and Support:

Advanced wet wipe packaging machines offer remote monitoring and support capabilities. Technicians can remotely access the machine for diagnostics, software updates, and troubleshooting, minimizing downtime and improving maintenance efficiency. Remote support ensures prompt assistance and reduces the need for on-site visits.

Integration with Supply Chain Systems:

State-of-the-art machines seamlessly integrate with supply chain systems for efficient inventory management, real-time tracking, and batch traceability. These integrations enhance visibility, streamline logistics, and ensure accurate stock control, leading to improved overall operational efficiency.

By investing in state-of-the-art wet wipe packaging machines, manufacturers can gain a competitive edge in the market. These machines streamline operations, increase productivity, enhance product quality, and align with sustainability goals. They empower manufacturers to meet the evolving demands of consumers while maintaining a high level of efficiency and innovation.